Spent Fuel Storage

Overview

Dry cask operations are a significant contributor to overall dose at plants who employ them. Recent trends of storing radiologically hotter fuel in dry casks and an increased push to reduce neutron dose exposure has made the implementation of dry cask shielding into the process even more important. Shield Bells, Annulus Gap Snakes, and Canister Lid Shields are usually used to supplement the gamma and neutron shielding provided by the Transfer Cask. The supplemental shielding reduces dose rates on the work platform during welding, weld inspection, and helium backfilling operation. NPO has worked directly with cask manufacturers, crews that move the fuel, and RP departments to create the most comprehensive and effective Dry Cask shielding in the industry.

NPO has shield bell, canister lid shielding, and annulus gap shielding offerings for each Dry Cask Manufacturer (Orano, NAC, Holtec). Since 2015, NPO has provided over 20 complete Dry Cask Shielding Packages (shield bell/lid shield).

Types of Shielding

Spent Fuel Storage Applications

Dry Cask Shielding Package

In 2019, Davis-Besse Nuclear Power Station, purchased an array of shielding from NPO for their spent fuel storage campaign. This package included a transfer cask shield bell, canister shield...

Vertical Storage Cask Gap Shielding

“Discrete exposure savings listed at 41 mrem [410 μSv]. However, the shielding also provided critical radiological configuration control during this high profile first time evolution.” -Timothy Bigler, Point Beach...

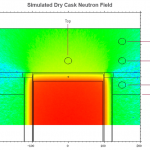

MCNP Case Study – Dry Cask Shielding

One year ago we introduced our new ability to simulate complex radiation profiles and thereby design the most effective shielding possible (‘NPO uses MCNP to simulate Dry Cask’, March...

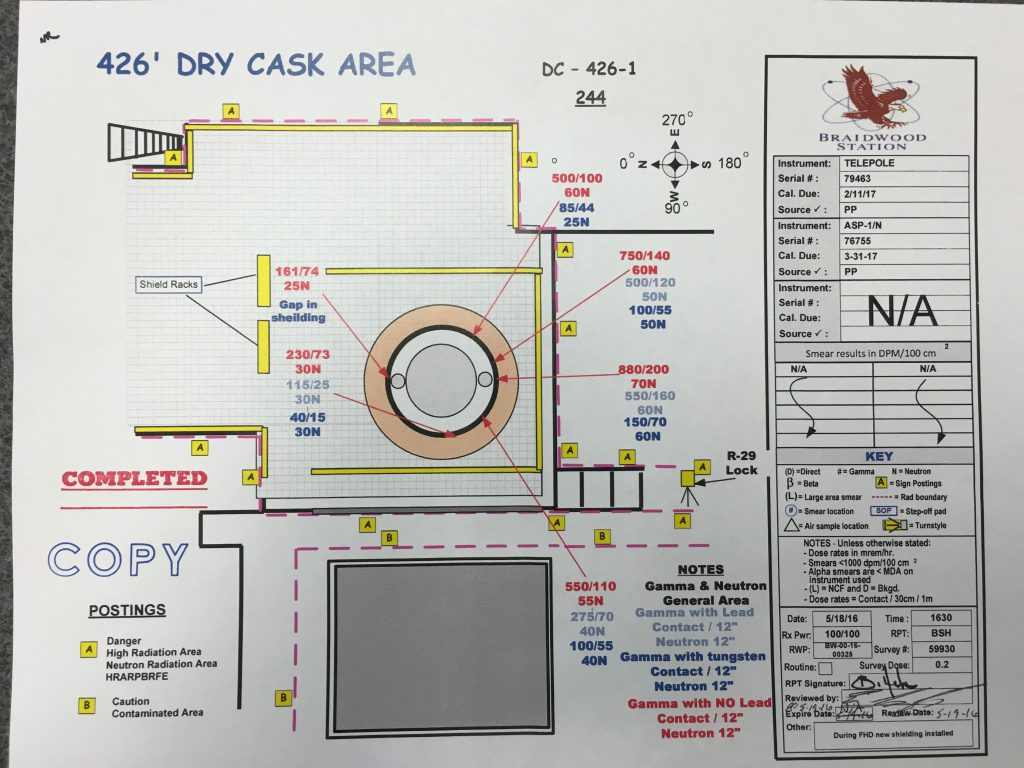

Braidwood Dry Cask Annulus Gap Snakes

Exelon Braidwood Station recently saw very good dose reduction with their dry cask campaigns by utilizing NPO T-Flex® Annulus Gap Shielding. This was designed to fit in the annulus...

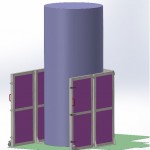

Lower Dry Cask Barrel Shield

Some NPP’s process Dry Casks in a such a way that the entire cask produces a general area dose concern. To reduce these dose rates NPO developed a shield...

NPO uses MCNP to simulate Dry Cask

Dry Cask processing operations present a number of complex radiological challenges. The presence of both neutron and gamma radiation coupled with the varying amounts of shielding already provided by...

Interested in learning more about our products?

Send us a message via our contact form, and we’ll answer any questions you may have.