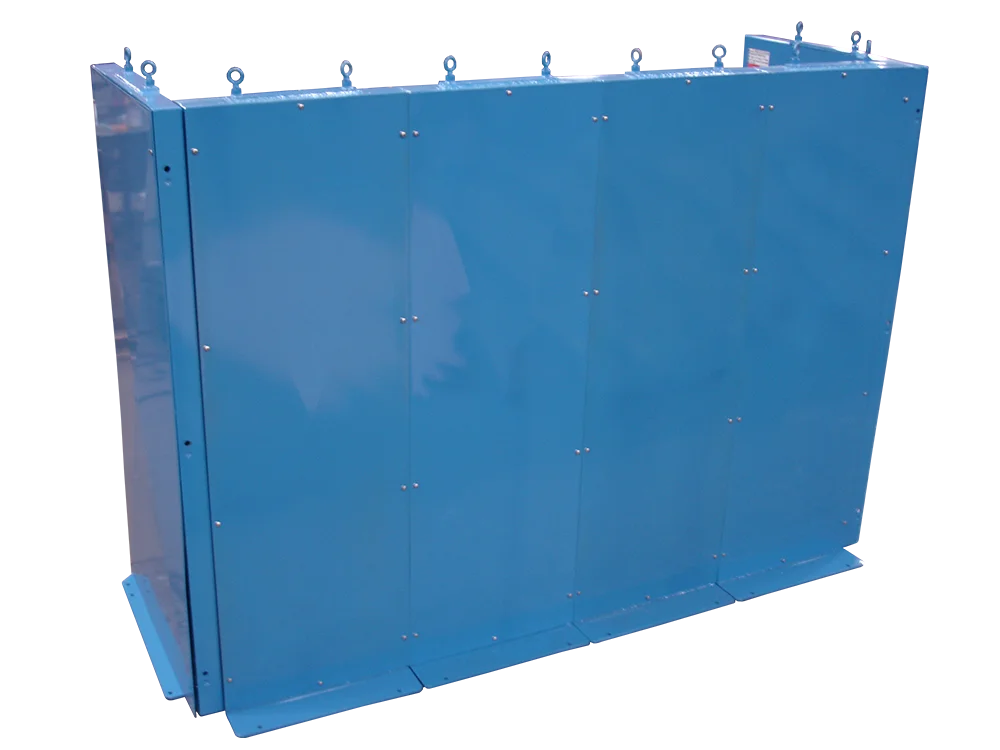

Lead + Steel Fabrication Overview

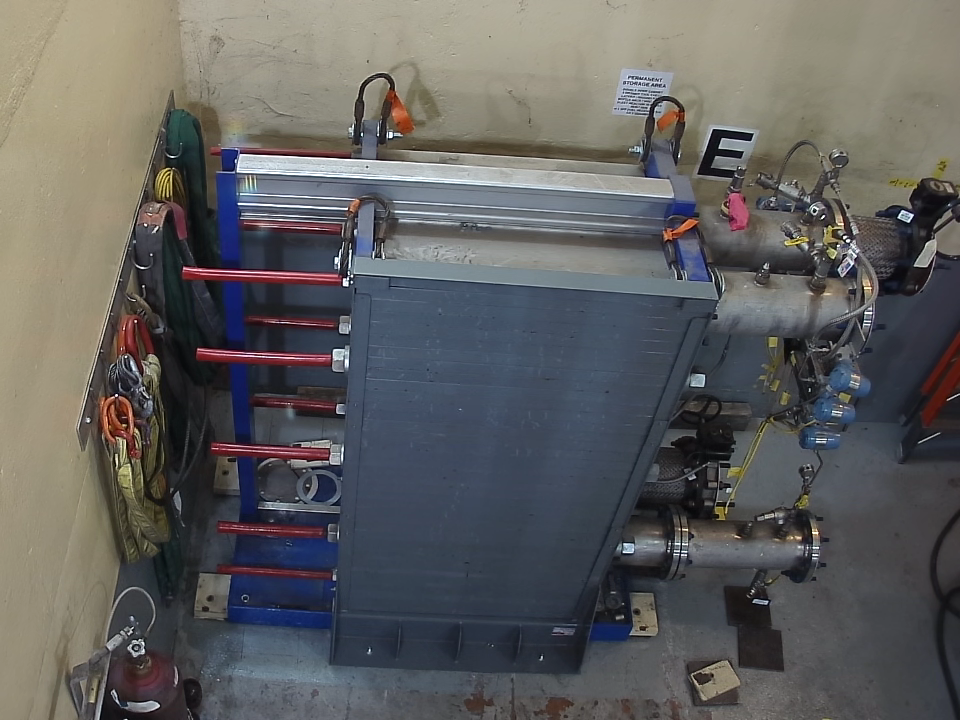

Lead + Steel Fabrications radiation shielding encase lead inside of carbon or stainless steel. Lead (Pb) is cost effective and offers excellent gamma attenuation properties. The attenuating properties of Lead are only surpassed by exotic and expensive materials such as Tungsten (W) and depleted Uranium (DU). However, exposed Lead poses EH&S hazards. Furthermore, industrial settings require more durability and strength than raw Lead can offer.

Encasing Lead in steel eliminates its hazards and weak material properties, while retaining its attenuation performance and cost effectiveness. The high temperature resistance and all steel exterior make it ideal for permanent shielding applications. Using structural steel simplifies 2:1 seismic analysis and eliminates GSI-191 sump concerns present in US Nuclear Power Plants.

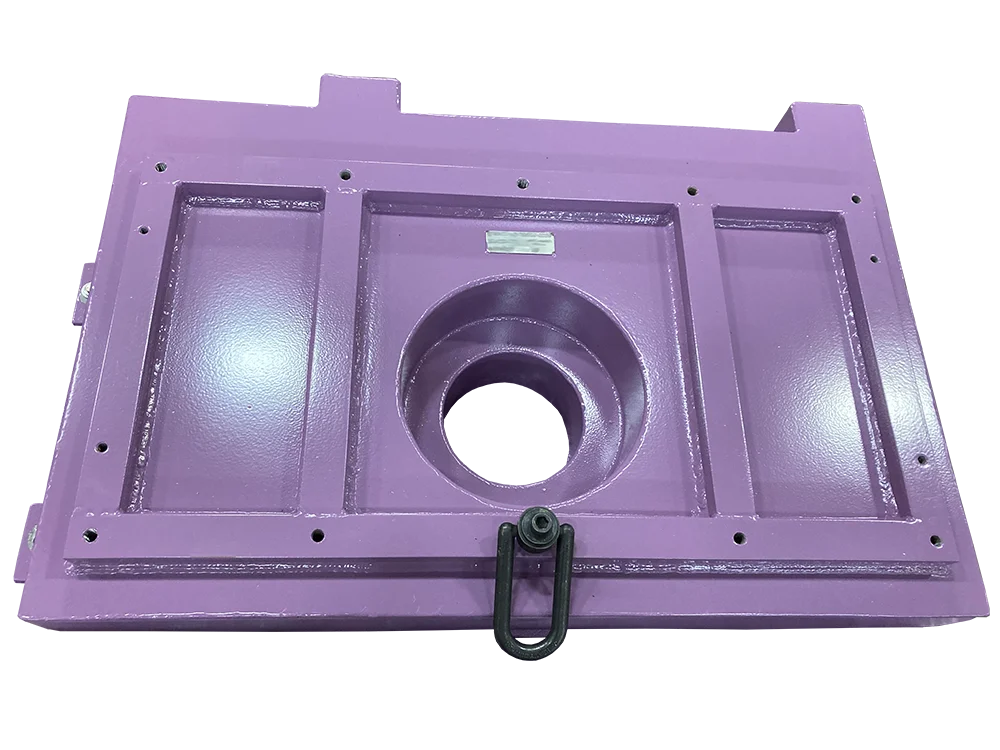

There are challenges to designing and manufacturing Lead encased in steel products. Pouring molten Lead into a steel enclosure can cause warping and make tight tolerances difficult to achieve. Post Lead pour machining can be complicated by the extreme weight. Using Lead plates in steel enclosures can result in radiation streaming.

NPO has been excelling at these challenges for over 30 years. We take on projects scaling from pounds to tons while achieving some of the most challenging tolerance scenarios.

Encasing Lead in steel eliminates its hazards and weak material properties, while retaining its attenuation performance and cost effectiveness.

There are challenges to designing and manufacturing Lead encased in steel products. Pouring molten Lead into a steel enclosure can cause warping and make tight tolerances difficult to achieve. Post Lead pour machining can be complicated by the extreme weight. Using Lead plates in steel enclosures can result in radiation streaming.

NPO has been excelling at these challenges for over 30 years. We take on projects scaling from pounds to tons while achieving some of the most challenging tolerance scenarios.

Products

- Custom fabrications

- Casks

- Pigs

- Radionuclide Generator

- Machined lead

- Lead pour

Services / QC

- ISO certified

- CSA W59 compliant fabrication

- AWS and ASME compliant welding

- ANST Weld Inspection

- ASME B30.20 – Below the Hook Lift Testing

- Gamma Source Testing

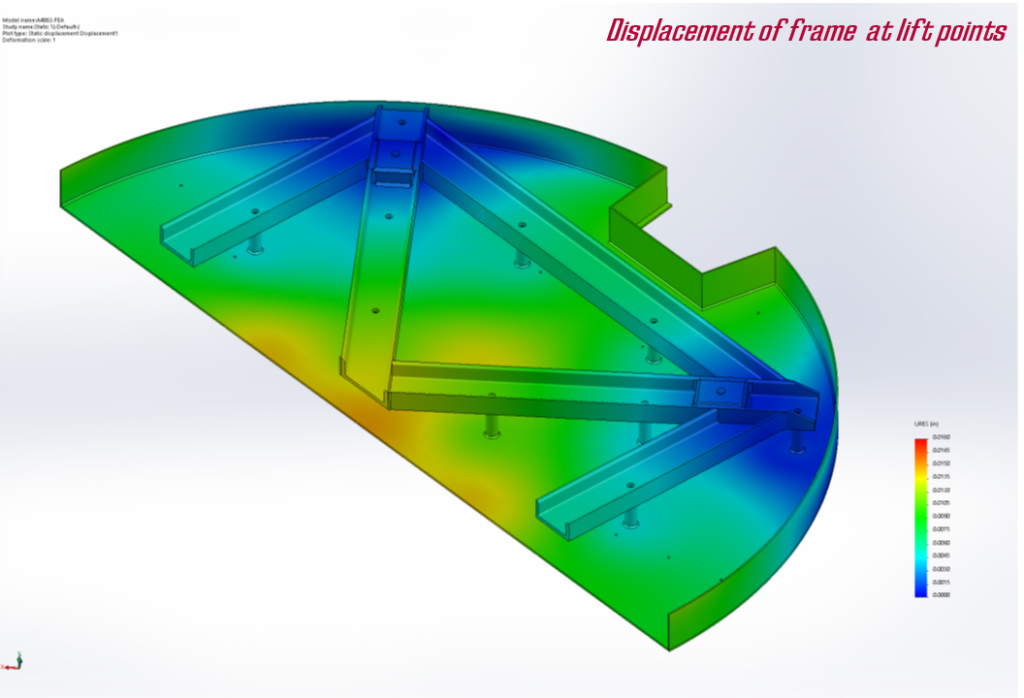

- Seismic/Structural Analysis

- Expedited delivery