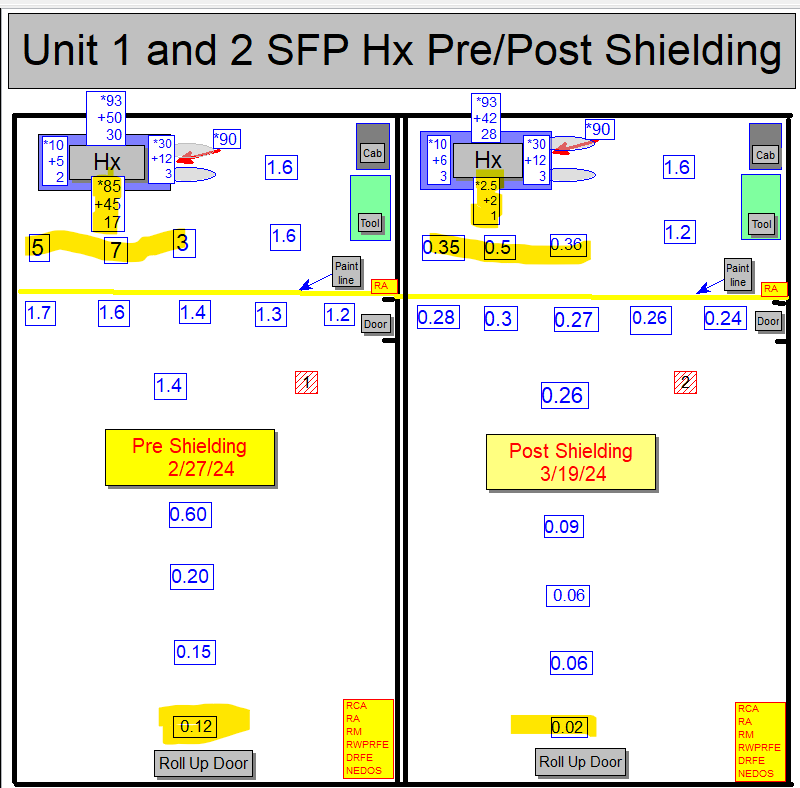

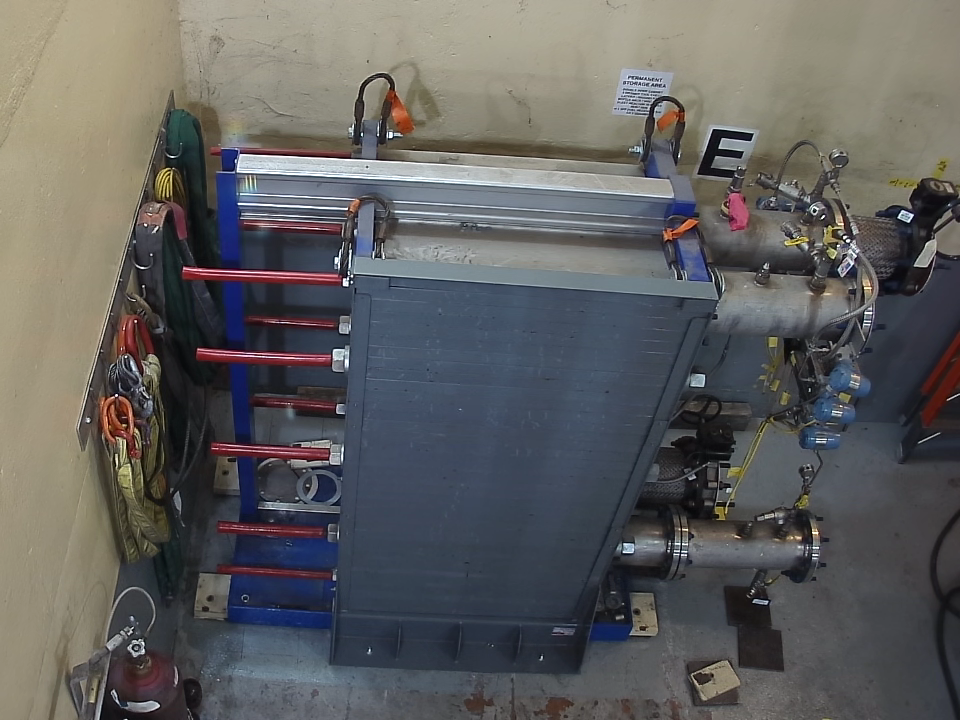

Oconee Nuclear Station contacted NPO to develop a permanent shielding solution for the Supplemental Spent Fuel Cooling Heat Exchanger. The heat exchanger is located inside the truck bay with one side exposed to the main truck bay door at the Radiologically Controlled Area (RCA) boundary. The ALARA planners at Oconee wanted a permanent shielding solution that would reduce the general area dose rates.

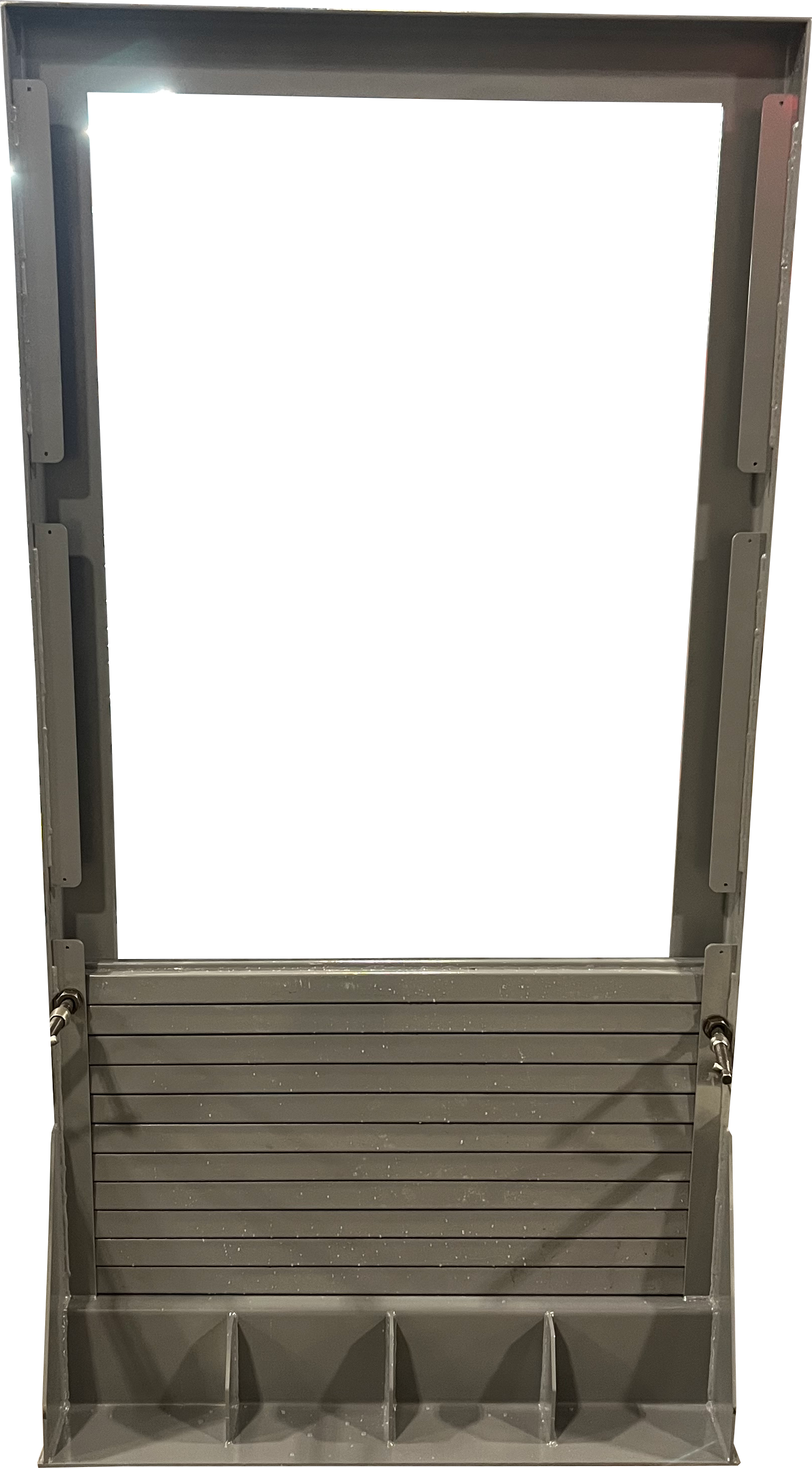

The NPO team developed a permanent solution that surpassed dose reduction goals. A carbon steel frame was designed that secured to the heat exchanger skid plates. Overlapping lead panels were installed into the carbon steel frame to prevent streaming. The frame and lead panels were deployed efficiently with minimal radiological exposure received by the Oconee team. The Oconee team placed industrial safety at the highest priority during install, achieving no events and zero injuries.

Post survey results confirmed greater than 95% dose reduction. The general area dose rate reduction achieved with this application will reduce the Oconee Stations annual exposure in this area. The Oconee ALARA team stated, “the shielding application has exceeded our expectations”.