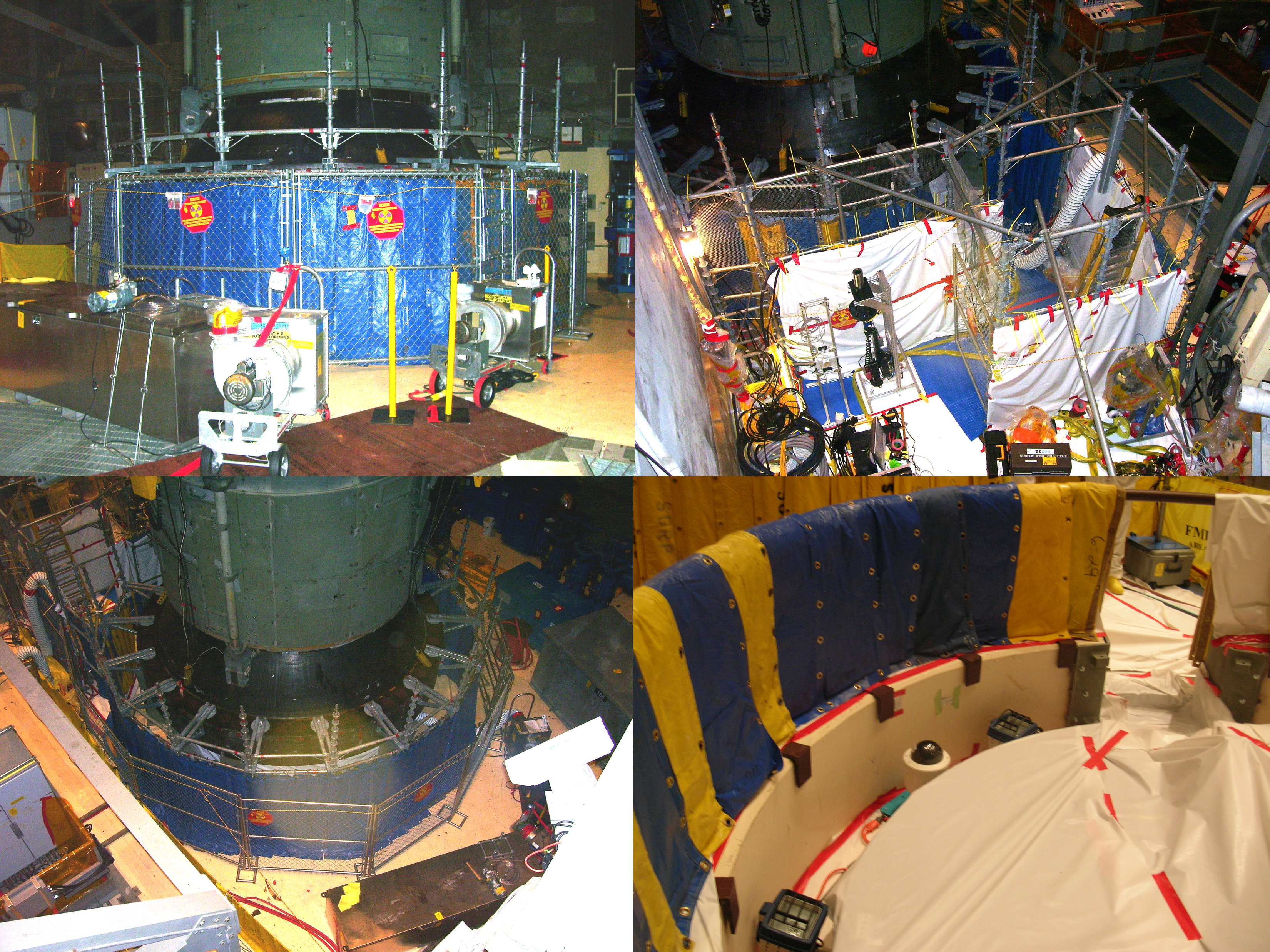

In 2021, Vogtle reached out to NPO to help develop a new shielding package for around the reactor head. Their current system consisted of two rings: one under the head, and one around the outside of the head. Each of these shield rings used 1’ x 6’ (305 mm x 1829 mm) 60 lb (27.2 kg) lead wool blankets. These shielding systems were cumbersome to install, incurred a lot of time and dose, and took up a lot of space, particularly the outer shielding ring.

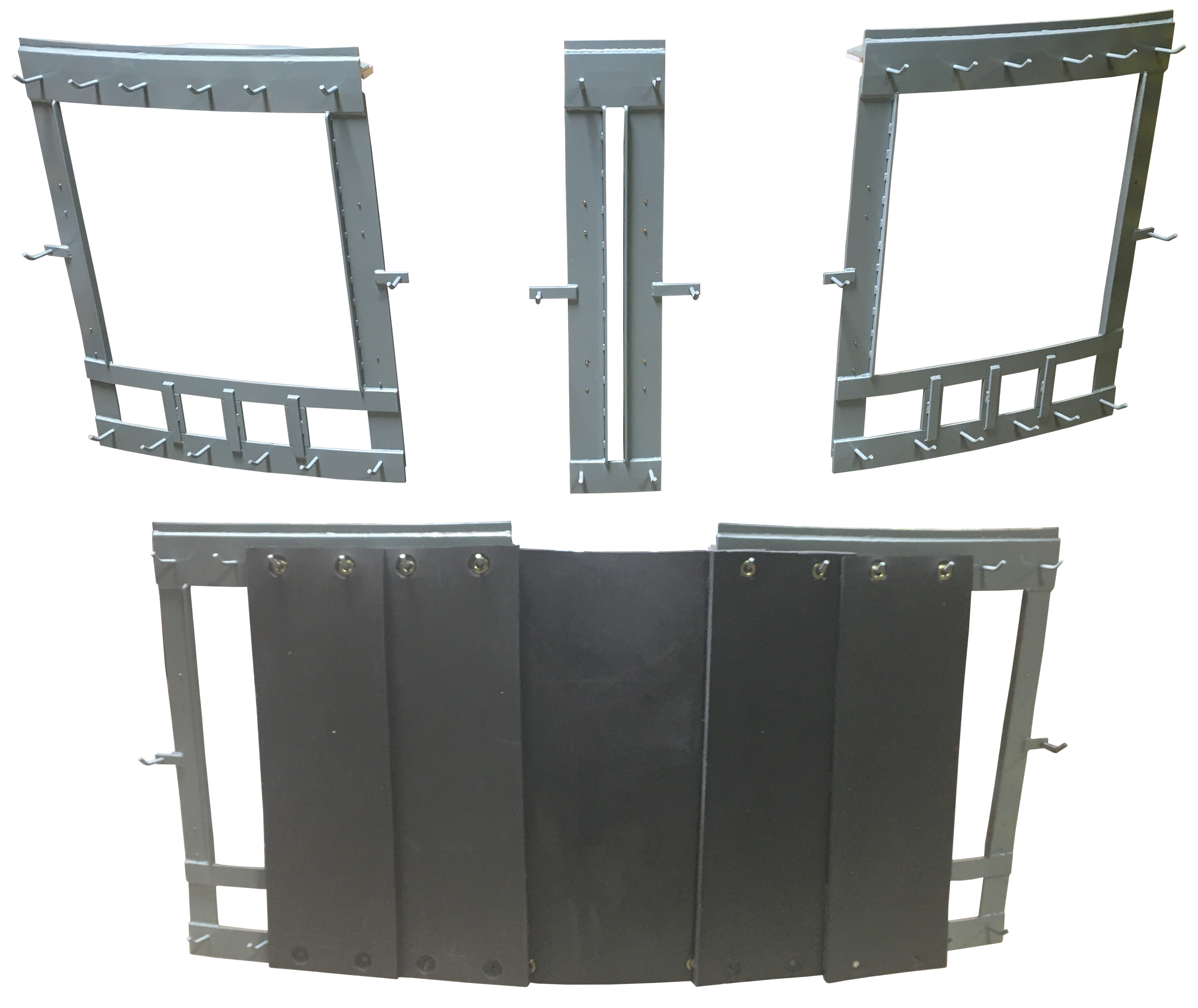

With close collaboration with Eric Fulghum, the RP Supervisor, the 1’ x 6’ (305 mm x 1829 mm) 60 lb (27.2 kg) lead wool blankets were replaced with 1’ x 3’ (305 mm x 914 mm) T-Flex Bismuth blankets, and a sleeker, easier to install rack system was employed around the reactor head flange.

Benefits:

Using the lighter weight blankets, the inner rings install time was reduced from 5 or 6 hours typically to less than an hour. This is partially due to the fact that the 60 lb (27.2 kg) blankets were a two-man lift, and the new 45 lb (20.4 kg) blankets can be safely handled by a single installer. The number T-Flex blankets ensured overlap between them to prevent streaming.

Improving the outer package was a more complicated problem to tackle. The old system also used 1’ x 6’ (305 mm x 1829 mm) lead wool blankets and they were attached to a scaffolding system. This scaffolding system then needed a fence erected around it to limit personnel access.

Between the inner and outer shielding, installation would take 12–13 hours and cost Vogtle between 150–200 mRem (1500–2000 μSv).

The new outer shielding system used sleek fitting racks that hugged the outside diameter of the reactor flange. The racks were secured to the flange by fitting into the stud holes and each one consisted of two rows of hooks for 1’ x 3’ (305 mm x 914 mm) T-Flex Bismuth blankets. This set-up was far less obtrusive than the previous one. This allowed for two things. First, the fencing surrounding the shielding was eliminated, freeing up floor space and greatly reducing installation time. Second, since the shielding was attached to the reactor head itself, thermal sleeve work under the head and core exit thermocouple work on top of the head were able to be done at the same time.

Vogtle managed to cut installation time to about 90 minutes total, about 8.5 times faster than before, drastically reducing dose taken along the way.

The new shielding package can be used on both units.