In 2025, Millstone Power Station faced a persistent dose rate challenge at a 45° elbow hot spot, where dose rates exceeded 20 Rem/hr. The existing temporary solution—shielding blankets wrapped around the pipe—was both visually unappealing and insufficient attenuation. Positioned overhead, the source posed unnecessary exposure to personnel working in the area.

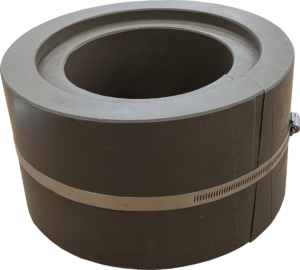

To address the issue, a custom-engineered T-Flex® Bismuth shielding package was implemented. Designed as a three-piece, form-fitted system, the shielding measured 2.25 inches thick and included integrated metal banding for secure installation. Each piece interlocked to eliminate streaming gaps, maximizing dose reduction while adhering to a 120 lb/linear foot weight limit on the pipe.

Although the hot spot had naturally decayed to 240 mRem/hr by the time of installation, the new shielding brought contact dose rates down to just 12 mRem/hr and reduced radiation levels to 0.8 mRem/hr at 30 cm—a nearly 95% reduction. The success of this project demonstrates the effectiveness of precision shielding design in enhancing worker safety and operational efficiency.

"It looks great, so much better than what was there before."

Health Physics Coordinator, Millstone